Consult. Train. Analyse.

Bolted Joint Design Specialists

What does Root Analysis do?

We help you design reliable bolted joints—tools, training, and consultancy. No fluff.

Who is it for?

Design/ME leads, quality engineers, and teams assembling critical joints.

What problems do you solve?

Loose joints, stripped threads, fatigue, leakage, unknown torque/preload. The unsolvable.

What do I get at the end?

Whatever you need and is agreed!

Can you review my design?

Yes—practical changes, risk ranking, and fast wins.

Do you train teams?

Yes—Essentials (1h) and Enhanced (4h). Remote first; group sessions available.

What's BoltLab?

Our standards-aligned calculator: transparent formulas, unit-aware, exportable results.

Can you build custom tools?

Yes—your materials, sizes, and workflows baked into BoltLab.

How do you handle sensitive data?

NDA friendly. Project data stays confidential.

How do we start?

Share your joint, constraints, and target torque/preload. We scope and go.

Training

Learn the core essentials of bolting. No fluff.

Essentials

- • Fundamental concepts clearly explained

- • Key traps to avoid, tips to use everyday

- • Applied case study

- • Q & A

- • Approx time: 1 hour

- • Sessions run weekly

Who's it for?

- • New to bolting

- • Technical / project leads (risk awareness)

- • Assembly technicians (error impact)

- • Anyone curious about bolting

Enhanced

- • Everything from essentials

- • Greater detail for enhanced understanding

- • Guided learning

- • Approx time: 4 hours

- • Special sessions can be arranged for groups

- • Sessions run Monthly

Who's it for?

- • Design engineers

- • Quality engineers

- • Teams wanting guided casework

- • Groups needing deeper dives

Values

Rooted in expertise

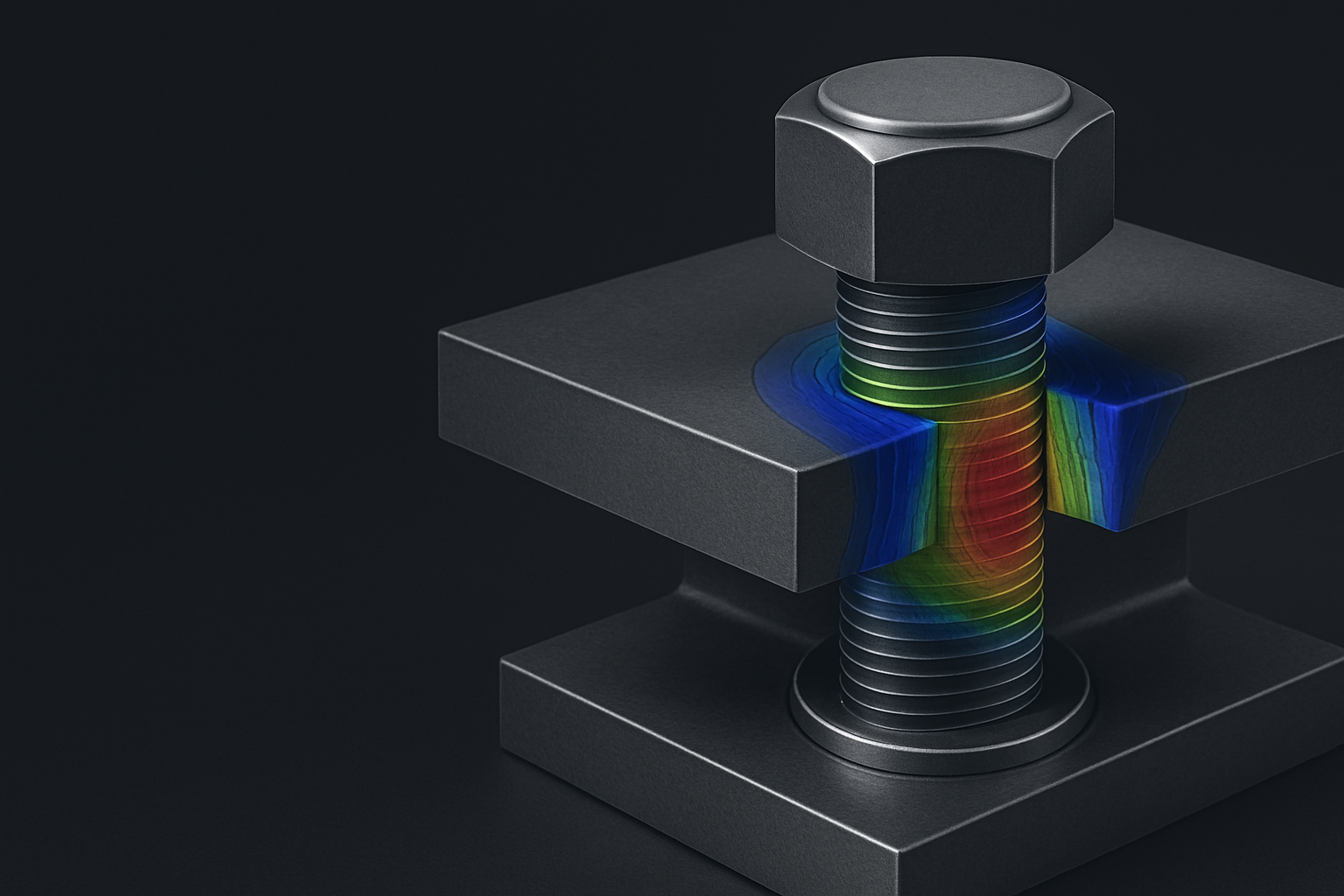

Root Analysis brings specialized knowledge in bolted joints, threaded fasteners, and structural analysis to every project. Our engineering solutions are grounded in rigorous analysis and real-world experience across a range of industries.

Relationships are critical for business. With Root Analysis you will have a true partner who can adapt to your business and provide access to a network of professionals that can make anything happen. Together.

Built on connection

Delivering Growth

We don't just solve problems – we add value, making an immediate impact on your business, whether through technical solutions or training. With Root Analysis as your partner, your challenges become opportunities for growth.

What does Root Analysis do?

We help you design reliable bolted joints—tools, training, and consultancy. No fluff.

Who is it for?

Design/ME leads, quality engineers, and teams assembling critical joints.

What problems do you solve?

Loose joints, stripped threads, fatigue, leakage, unknown torque/preload. The unsolvable.

What do I get at the end?

Whatever you need and is agreed!

Can you review my design?

Yes—practical changes, risk ranking, and fast wins.

Do you train teams?

Yes—Essentials (1h) and Enhanced (4h). Remote first; group sessions available.

What's BoltLab?

Our standards-aligned calculator: transparent formulas, unit-aware, exportable results.

Can you build custom tools?

Yes—your materials, sizes, and workflows baked into BoltLab.

How do you handle sensitive data?

NDA friendly. Project data stays confidential.

How do we start?

Share your joint, constraints, and target torque/preload. We scope and go.

As a chartered mechanical engineer with over a decades worth of experience, when you choose Root Analysis you are choosing a professional partner committed to delivering high quality expertise tailored to your needs. What's more, just like our clients, Root Analysis is unique. Through an extensive network of professionals across a variety of talents and industries, we are capable and excited to meet any challenge that our customers face.

Stephen Saxby, CEng IMechE, MEng First Class, Founder